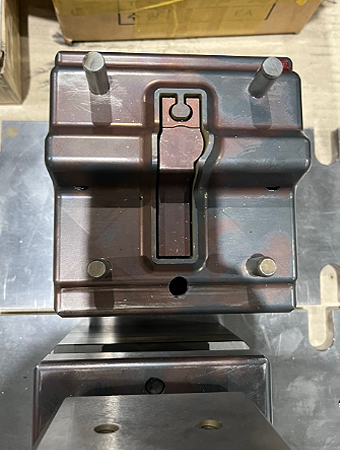

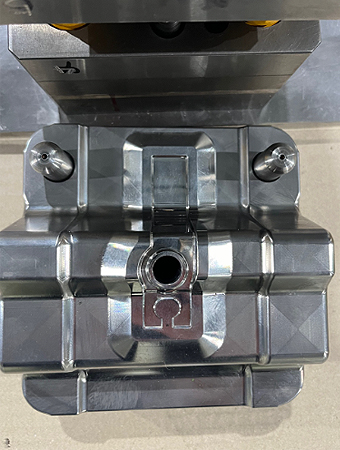

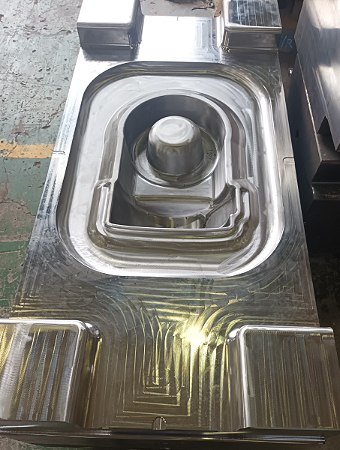

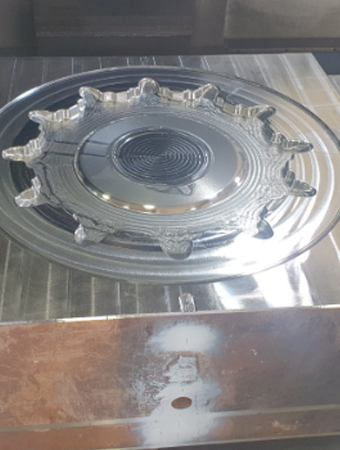

Forging Mold

1. COUNTER BLOW HAMMER

The counterblow hammer has two rams that approach each other horizontally or vertically to forge the product. In open die forging, the material is rotated at a fixed angle with each strike to achieve the desired shape. The counterblow hammer operates at high speed but does not cause significant vibration to the support. Its capacity reaches up to 1,200 KJ.

2. AIR DROP HAMMER

The air drop hammer gains energy from a ram that free falls. The energy obtained from this type of hammer is the product of the ram's weight and the height it is lifted during the fall. The ram's weight ranges from 180 kg to 4,500 kg, and the energy capacity can reach up to 120 KJ.

3. PRESS

The mechanical press primarily utilizes a crank mechanism or eccentric type, where the speed reaches its maximum at the midpoint of the stroke and becomes zero at the end of the stroke. Instead of an eccentric shaft, a crankshaft can be used to facilitate the vertical movement of the ram. Thus, the mechanical press has a limited stroke. The rotational motion is converted into linear reciprocating motion through the connecting rod, resulting in a very high production rate and ease of automation.

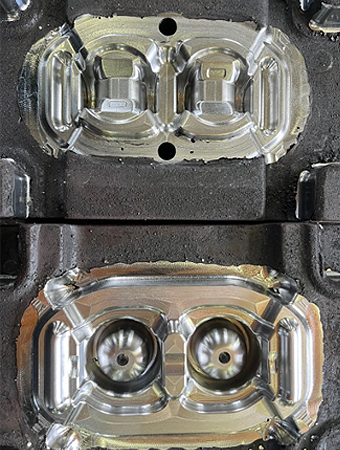

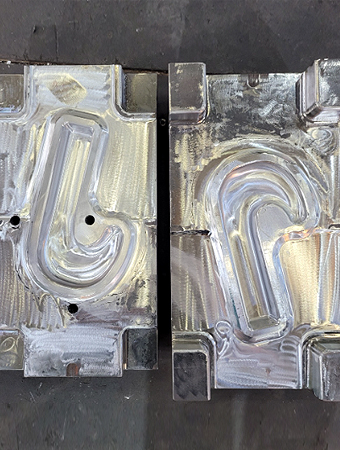

・ Automotive mold

・ Heavy equipment mold

・ Non-ferrous forging mold